- Published on

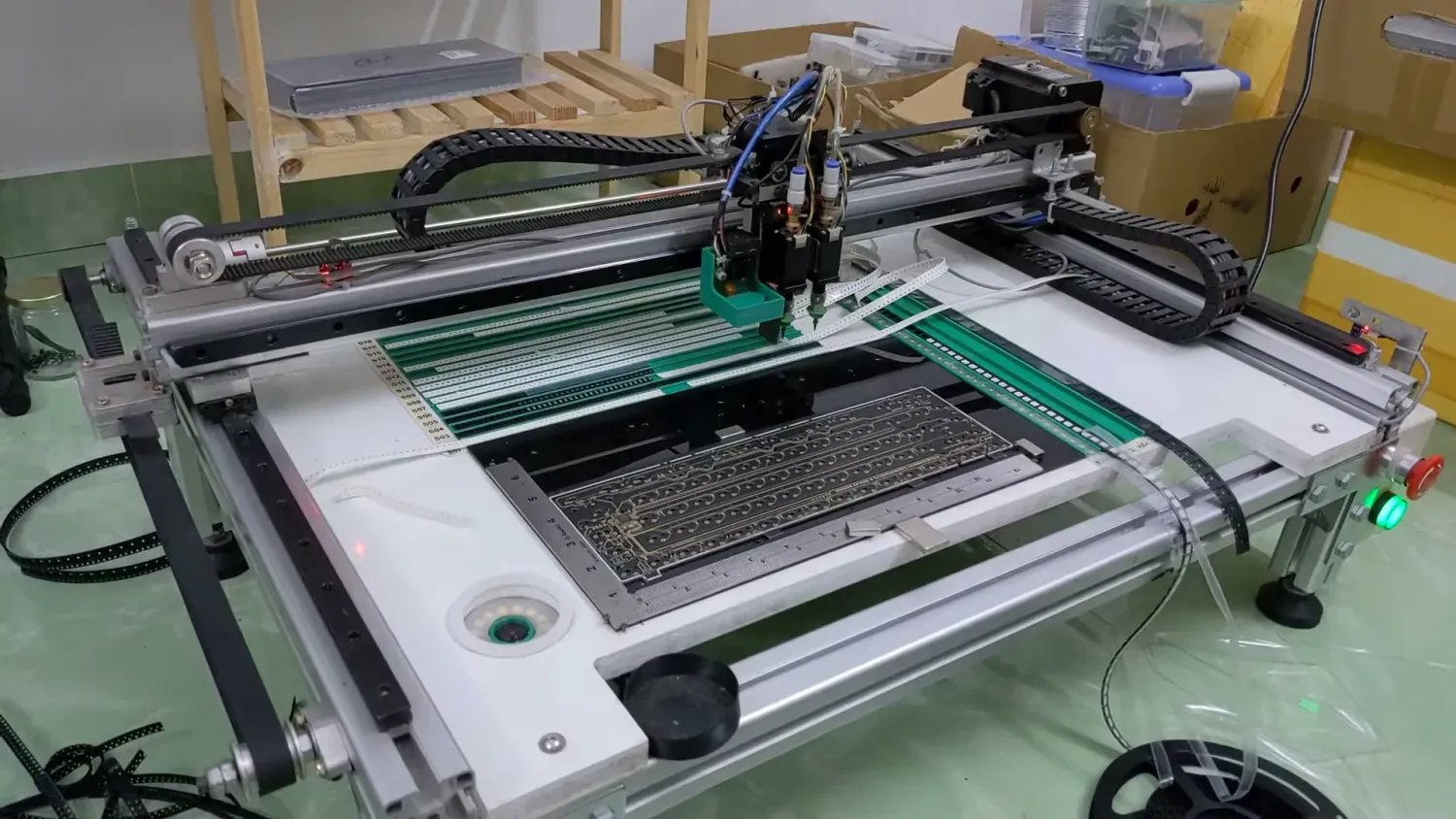

Building a SMT Pick & Place Machine

- Authors

- Name

- Mai H. Son (Mason)

Motive

Hand-soldering SMD components is a tedious task, even if it is's for a hobby project. For prototype projects that needs short feedback cycles and low-cost assembly, a mini pick and place machine is a great addition to the workshop.

After some research, I decided to build one my own. The goal was to build a machine that is:

- Affordable: The machine should be affordable for hobbyists and makers.

- Compact: The machine should be small enough to fit on a desk.

- Easy to use: The machine should be easy to use and set up.

Design

The machine use a dual-head / dual-vision design, which means that it has two heads that can pick and place components, and two cameras that can detect the position of the components. This allows the machine to pick and place components quickly and accurately.

The working area is about 800x680mm, including tape and PCB holder, which is more than enough for most hobby projects, and can assemble multiple PCBs at once.

The nozzles can be calibrated to pick up components of small size down to 0402, and the machine can place components with a pitch of 0.5mm.

It use neumatic valves and pumps for suction/ release.

Specifications:

- 2 stepper servos (NEMA 17) for X and Y axis

- 1 stepper motor for Z axis (controling both heads)

- 2 stepper motors for the nozzles rotation

- 1 vacumm pump, 1 blow pump, 2 pneumatic valves for each nozzle

- 2 5MP cameras for top and bottom vision

[...continue]

Comments powered by Talkyard.